05 Aug 2025

How PVC Pipes Drive Efficiency in Industrial Applications?

PVC pipes find their purpose in diverse industrial operations across various sectors, like chemical processing and water treatment facilities. These adaptable industrial pipes build the foundation of contemporary industrial infrastructure for transporting vital fluids and materials while preserving the system’s integrity. They are durable, corrosion-resistant and cost-effective, which makes PVC pipes an ideal choice for industrial applications. These chemical pipes made of PVC are extremely durable and require minimal maintenance. This means lower operational downtime, labour costs and increased operational efficiency for businesses.

Read on to know how these chemical pipes made from PVC make industrial operations more efficient.

Understanding PVC Pipes and their Types

Polyvinyl Chloride or PVC pipes are thermoplastic tubes manufactured from a synthetic polymer compound. The base material consists of PVC resin mixed with stabilisers, lubricants and pigments to create a durable piping solution. PVC pipes and fittings can survive well under extreme temperatures and pressure, and do not rust easily. These chemical pipes made with PVC are also lightweight, which makes transportation and installation much easier than metal pipes.

There are two primary types of PVC pipes:

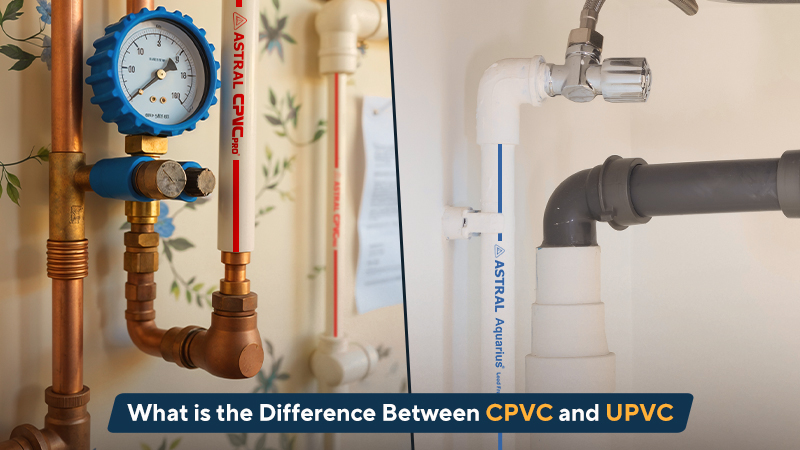

1. CPVC: CPVC is a type of PVC that has been chlorinated, which gives it higher temperature resistance. It also maintains good chemical resistance and mechanical strength. This makes CPVC pipe suitable for industrial piping in higher temperatures.

2. uPVC: uPVC stands for Unplasticised Polyvinyl Chloride. It has high tensile strength, which makes it very strong and durable. uPVC pipes are resistant to chemicals, which makes them ideal for chemical engineering or treatment plants.

Benefits of PVC Pipes in Industrial Piping System

1. Chemical Resistance

PVC pipes and fittings can withstand exposure to aggressive chemicals, acids, alkalis and salts. They maintain their structural integrity even when transporting corrosive industrial fluids. PVC pipes resist chemical damage caused by oils and most solvents. This makes pVC pipes a reliable option even in demanding environments.

2. Superior Mechanical Properties

PVC pipes have a tensile strength of up to 7,000 psi, which allows them to bear heavy loads. Their high stiffness prevents the chemical pipes from bending or warping under pressure. Such high impact resistance protects these industrial pipes from physical damage and helps them maintain their shape across various temperatures.

3. Extended Service Life

PVC pipes and fittings can last between 50 to 100 years under proper upkeep and maintenance. They do not rust or corrode, which contributes to their longevity. These industrial pipes require minimal maintenance without many disruptions, maintaining a smooth workflow. UV-stabilised versions of PVC pipes are also available to resist environmental damage.

4. Hydraulic Efficiency

The smooth interior walls of PVC pipes reduce friction loss by 15% to 40%. This means less energy is required for pumping fluids, which helps to lower operational costs. The chemical pipes made from PVC can prevent the build-up of deposits. As a result, they maintain steady flow rates throughout their lifespan.

5. Cost Benefits

PVC pipes are 40-60% lighter than metal alternatives, which makes them easier to install and transport. These industrial pipes can be quickly installed using solvent cement joints. They have lower costs because they require minimal maintenance, which results in lower long-term expenses than traditional industrial pipes.

Top-Grade Industrial Pipes by Astral Pipes

At Astral Pipes, we design and deliver high-quality industrial pipes to enhance operational efficiency in multiple industries.

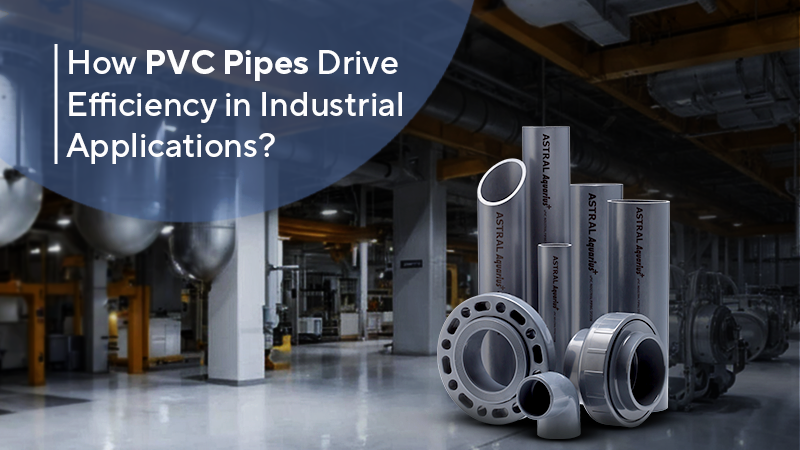

Astral Chem Pro: CPVC Industrial Piping System

Our Chem Pro is a range of chemical-resistant PVC pipes, engineered specifically for handling aggressive chemicals safely and efficiently. These industrial pipes are resistant to concentrated acids, alkalis, industrial solvents and saline environments. These qualities make them ideal for use in chemical processing plants, pharmaceutical industries and other sectors where chemical integrity is paramount. The robust design ensures extended service life even under harsh industrial conditions.

Astral Aquarius+: uPVC Industrial Piping System

Aquarius is a uPVC industrial piping solution, used for water supply and wastewater management in large industrial settings. These chemical pipes are designed for hydraulic efficiency with smooth interiors to reduce friction losses and prevent sediment build-up. The uPVC pipes are well-suited for transporting potable water, irrigation systems and effluent disposal. They offer unmatched durability and cost-effective solutions that support sustainable water management practices.

These industrial piping systems are ideal solutions for multiple industrial applications due to their excellent temperature and pressure resistance. At Astral Pipes, we prioritise quality and reliability to ensure our PVC pipes meet industry requirements consistently and perform effectively in challenging industrial environments.

Reliable Industrial Drainage Solutions with PVC Pipes

Selecting the right pipes for industrial drainage is key to maintaining smooth operations across industries. PVC pipes and fittings are the best option, offering impressive strength, easy installation and lasting durability. These qualities are what make them the go-to solution for industries around the globe. Explore our selection of PVC pipes and fittings for industrial drainage to find the right fit for your needs. Built with top-grade materials for tough industrial environments, these industrial pipes offer consistent performance, low maintenance and exceptional durability over time.