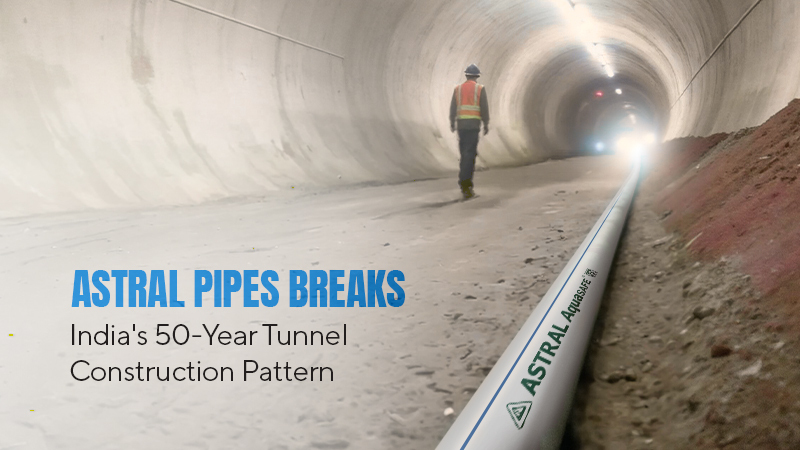

Astral Pipes Breaks India’s 50-Year Tunnel Construction Pattern

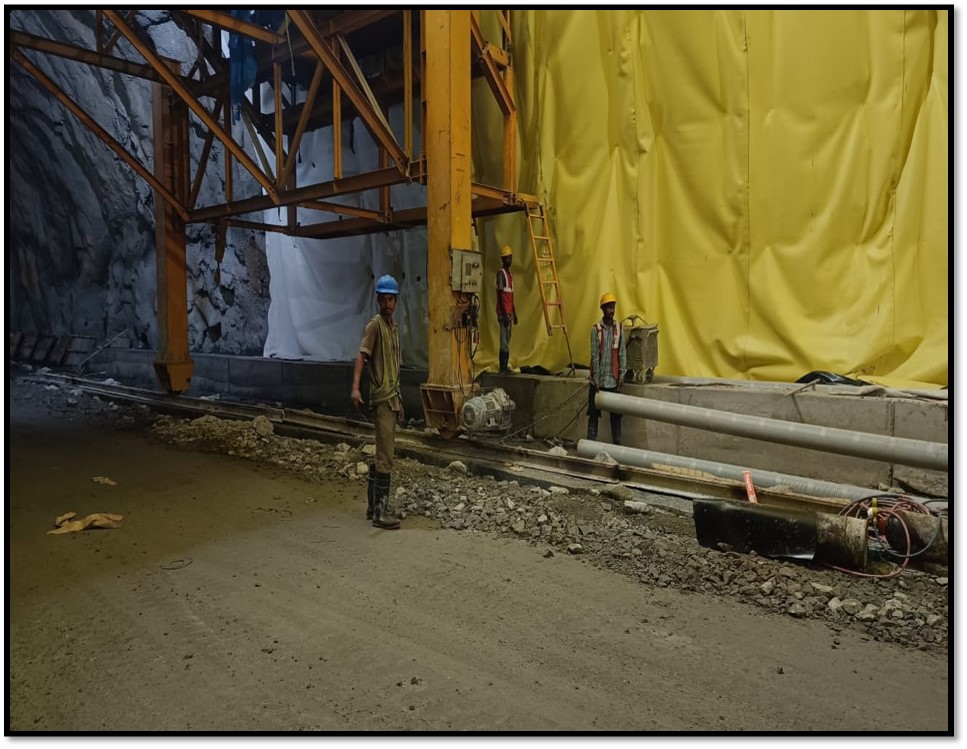

Location : Orissa

Product Type : Aquasafe

When NHAI approved PVC pipes for the 7-kilometre Koraput tunnel project in Odisha, this decision did more than enable a tunnel drainage system. It broke a 50-year pattern that had been wasting taxpayer money and slowing India’s infrastructure growth.

The Challenge: An Industry Stuck in Expensive Construction Habits

For five decades, India’s tunnel construction followed the same expensive playbook: use RCC pipes for water systems. This created an entire business ecosystem that made money from fixing problems instead of preventing them.

The Koraput tunnel project exposed how much this old approach was costing India.

The RCC Money Trap

- Guaranteed Replacements: Every tunnel with RCC pipes needs complete replacement every 20 years, forcing taxpayers to pay for the same infrastructure over and over

- Built-in Business Model: RCC suppliers and contractors designed their companies around these predictable failures and repairs

- No Innovation Pressure: Engineering firms had no reason to find better solutions when the old way guaranteed steady work

- Budget Waste: Government money kept going to fix old tunnels instead of building new ones

What Kept India Stuck in the ‘Expensive Fixes’ Cycle?

- Old Specifications: NHAI’s tunnel requirements hadn’t been updated in decades

- Risk-Free Thinking: Government projects chose “safe” options even when they were wasteful

- Protected Supply Chain: Companies built around RCC fought against changes that would hurt their profits

- Knowledge Gaps: Engineers weren’t exposed to better alternatives that could end the replacement cycle

Astral’s Solution: Challenging Five Decades of Expensive Thinking

Astral didn’t just offer 1,158 Aquasafe pipes, Astral questioned why India was accepting expensive, short-lived solutions. The Aquasafe PVC system directly challenged an industry that had gotten comfortable with planned failure.

What Astral Delivered?

- System: 1,158 units of 200mm Aquasafe PVC pipes (6 kg/cm² pressure rating)

- Immediate Savings: ₹15 lakh less than the equivalent RCC installation

- Application: Complete replacement of traditional RCC water supply systems

- Standards Met: IS: 4985 compliance proving PVC could meet the same requirements as RCC

- Real Goal: Prove that tunnel construction habits were built on outdated thinking

Why Does This Threaten Everyone?

Astral’s system challenged every assumption that kept the expensive RCC system alive:

- Instant Cost Cut: Lower project cost with better performance

- No Maintenance Needed: Zero scheduled maintenance directly threatened companies that made money from tunnel upkeep

- Lasts 50 Years: Versus RCC’s 20-year lifespan, meaning much less repeat business for traditional suppliers

- Easy Installation: Lightweight design needed less labour and equipment, threatening established contractor relationships

- Half the Annual Cost: Forced every tunnel project to explain why they weren’t using PVC

Making It Happen: Changing Minds, Not Just Materials

The real challenge was convincing NHAI to break decades of habit. Astral had to overcome the institutional barriers that protected the expensive RCC system.

- Creating the Precedent: NHAI’s approval of PVC pipes for Koraput created a precedent that every future tunnel project would have to address. Once proven viable, PVC became a legitimate option that forced everyone to justify continued RCC use.

- Breaking Technical Objections: By meeting IS: 4985 standards, Astral eliminated the safety and compliance arguments that had protected RCC’s market position. The successful installation proved that better performance was possible with lower costs.

Results: Lakhs Saved as Proof India Could Build Smarter

The Koraput tunnel created effects far beyond its immediate installation, fundamentally changing how India thinks about tunnel construction.

Immediate Money Impact

- ₹15 Lakh Saved: Proved that PVC wasn’t just technically better but financially smarter

- 50% Lower Running Costs: Ongoing savings throughout the system’s 50-year life

- 2.5x Better Value: Lifecycle advantage made continued RCC use financially stupid

- Budget Freedom: Maintenance savings could fund new infrastructure instead of repairs

Market Disruption Across Three Sectors

- Old Specs Look Wasteful: Made NHAI’s traditional tunnel specifications appear outdated and expensive

- Suppliers Under Pressure: RCC companies and maintenance contractors faced potential market loss across India’s tunnel network

- Engineers Must Adapt: Technical teams had to update design standards that hadn’t changed in decades

The Scaling Opportunity

- ₹2 Crore Potential: A 100-kilometre tunnel network could save over ₹2 crore using PVC systems

- National Scale Impact: With India’s growing tunnel network, cumulative savings could reach hundreds of crores

Impact: A Precedent That Questioned the RCC Monopoly

The Real Change:

Astral made every RCC pipe manufacturer in India’s tunnel sector question their future. By getting NHAI to officially approve PVC for tunnels, we created a precedent that changed competitive dynamics across India’s infrastructure sector.

What Does This Mean For The Tunnel Industry Key Players?

- Market Disruption: Traditional RCC suppliers lost their protected position in tunnel projects

- Engineering Evolution: Every tunnel design firm had to retrain teams and update specifications to stay competitive

- Business Model Threat: Companies built around RCC maintenance revenues faced potential obsolescence

The New Benchmark: The Koraput tunnel created an undeniable standard. PVC systems save ₹15 lakh per project while performing better. Every future tunnel proposal must now explain why they are choosing to waste taxpayer money on more expensive, shorter-lived alternatives.

What Really Happened?

The Koraput tunnel project turned Astral from a pipe supplier into the catalyst that ended India’s 50-year tunnel construction pattern. This single installation didn’t just save cost, it potentially saved India billions by breaking an industry habit that had prioritised maintenance revenue over infrastructure efficiency for half a century.