12 Jan 2026

What is the Difference Between CPVC and uPVC?

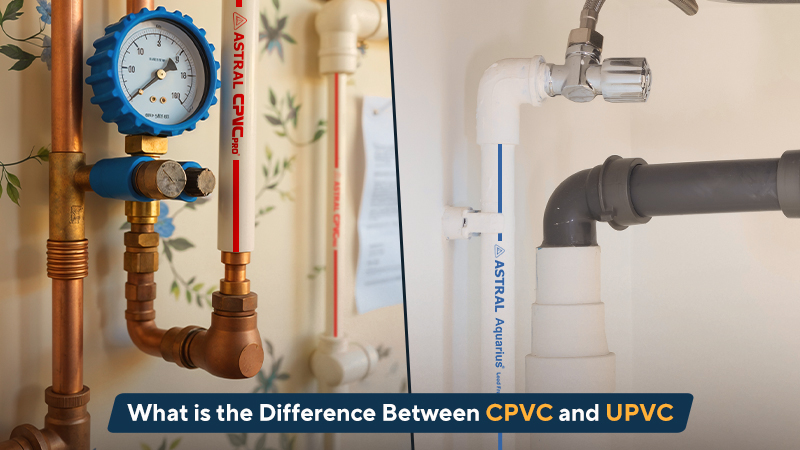

Every construction project is unique, whether you are building a home, setting up a commercial space or designing an industrial facility. One common yet important aspect in all of these is the choice of piping. Among the wide range of piping materials available today, CPVC pipes and uPVC pipes are two of the most commonly used choices in residential, commercial and industrial projects. Selecting between a CPVC pipe and uPVC pipe may seem like a minor decision, but it can greatly impact the performance, safety and longevity of your plumbing system. Understanding the difference between CPVC and uPVC is essential to make an informed and cost-effective choice. Let us explore how each material performs and where it best fits.

What are CPVC Pipes?

A CPVC pipe (Chlorinated Polyvinyl Chloride) is a thermoplastic piping solution made by chlorinating PVC resin. This process enhances its heat resistance, making it ideal for both hot and cold water applications. A CPVC pipe can withstand temperatures up to 93°C, making it a preferred choice for residential, commercial and industrial plumbing. Its corrosion resistance and compatibility with a wide range of chemicals make it suitable for HVAC systems, laboratories and even fire suppression systems. With high durability and long service life, CPVC pipes offer a reliable plumbing solution for demanding environments.

What are uPVC Pipes?

uPVC pipes (Unplasticised Polyvinyl Chloride) are rigid and strong pipes made without the addition of plasticisers, which are commonly used to make materials more flexible. As a result, uPVC pipes retain their shape and strength over time. They are non-toxic, lead-free and widely used in plumbing systems for potable cold water. These pipes can tolerate temperatures up to 60°C and offer excellent resistance to chemical corrosion, UV rays and environmental stress. Thanks to their durability and low maintenance needs, uPVC pipes are commonly used in agriculture, drainage, irrigation and residential plumbing systems.

Key Differences Between CPVC and uPVC Pipes

| Feature | CPVC (Chlorinated Polyvinyl Chloride) | uPVC (Unplasticized Polyvinyl Chloride) |

| Chemical Composition | PVC with added chlorine for extra thermal resistance | Rigid PVC without plasticisers |

| Temperature Tolerance | Up to 93°C | Up to 60°C |

| Usage | Suitable for hot and cold water | Suitable for cold water and drainage |

| Flexibility | More flexible than uPVC | More rigid and less flexible |

| Cost | Generally more expensive | More affordable |

| Chemical Resistance | Excellent, even in aggressive chemical environments | Good, but not ideal for high-temperature chemicals |

| Durability | Long lifespan, even under high temperatures | Durable in non-thermal stress environments |

| Certifications | Can have global approvals like NSF, UPC, BIS | Commonly used in domestic water and agriculture systems |

This is the difference between CPVC and uPVC, especially in terms of temperature handling, cost and application suitability. The choice between CPVC and uPVC pipes largely depends on their temperature tolerance, pressure requirements, and intended application environments.

Applications of CPVC vs uPVC Pipes

Applications of CPVC Pipe

- Hot and cold water plumbing in residential buildings

- Fire sprinkler and suppression systems

- Chemical and industrial fluid transport

- HVAC installations in hospitals, labs and commercial units

- High-pressure systems requiring heat resistance

Applications of uPVC Pipes

Cold water plumbing and potable water distribution

- Agricultural irrigation and farm water systems

- Rainwater drainage and waste disposal

- Electrical conduits for safe wire protection

- Industrial ventilation and non-pressurised systems

Both CPVC and uPVC pipes offer distinct advantages based on temperature handling, application type, and long-term performance requirements.

Advantages of CPVC and uPVC Pipes

Advantages of CPVC Pipe

- Handles hot water up to 93°C

- Resistant to corrosion, scale and aggressive chemicals

- Smooth interior surface enhances flow efficiency

- Low thermal conductivity helps conserve energy

- Long lifespan in both residential and industrial setups

Advantages of uPVC Pipes

- Non-toxic and lead-free, safe for drinking water

- Lightweight and easy to handle during installation

- Budget-friendly and cost-effective for large-scale projects

- Excellent UV and chemical resistance

- Minimal maintenance is required over time

Which Should You Choose: CPVC or uPVC?

Your final choice depends on the requirements of your project. If your plumbing needs include hot and cold water, a CPVC pipe is the way to go. Astral’s CPVC Pro Hot and Cold Water Plumbing System can handle temperatures up to 93°C and is certified by top international standards like NSF, UPC-1 and BIS. It is ideal for robust plumbing setups in homes and commercial spaces.

On the other hand, for safe and reliable cold water transport, Astral Aquarius Lead-Free uPVC Piping is a good choice. With a maximum service temperature of 60°C, these uPVC pipes offer a dependable solution for potable water applications while being eco-friendly and durable.

The difference between CPVC and uPVC lies in temperature tolerance and application suitability. While a CPVC pipe is designed for high-temperature, pressurised systems, uPVC pipes are best for cold water distribution, drainage and general plumbing. Both options offer durability, safety and excellent performance when used correctly. By choosing quality solutions from a trusted brand like Astral Pipes, you ensure that your project is built on a solid, efficient and long-lasting plumbing foundation.